Tempered glass selection determines whether architectural projects succeed or face costly failures. Inferior tempering creates safety risks, optical distortions, premature failures. Quality tempered glass manufacturer companies provide consistent products meeting safety standards, optical clarity, maintaining design intent, and reliability, preventing callbacks and destroying profit margins. Commercial and architectural projects demand manufacturers with proven capabilities beyond residential glazing operations.

The tempering process transforms ordinary glass into safety glass through controlled heating and rapid cooling. Done correctly, glass becomes four to five times stronger than annealed glass, breaking into small granular pieces instead of dangerous shards. Done poorly, glass includes stress concentrations causing spontaneous breakage, optical distortions ruining facades, or inadequate strength defeating safety purpose. Manufacturing quality separates reliable suppliers from liability risks.

Best 5 Tempered Glass Companies

Jersey Tempered Glass

Jersey Tempered Glass leads tempered glass manufacturer options through comprehensive capabilities serving commercial and architectural demands. Their tempering facilities process glass from 3/16" to 3/4" thickness accommodating various applications - storefront glazing, interior partitions, doors, railings, canopies. Equipment handles oversized panels architectural projects require - glass up to 96" x 130" providing design flexibility avoiding visible joints.

Quality control includes stress verification on every panel. Polarized light examination reveals stress patterns confirming proper tempering. Inadequately tempered glass shows stress concentrations indicating weakness or breakage risk. This inspection catches problems before glass reaches projects preventing field failures and liability. Optical quality maintained through precise temperature control during processing. Uneven heating creates roller wave distortion - visible ripples ruining appearance. Jersey Tempered Glass's tempering furnaces maintain temperature uniformity preventing distortion. Glass exits process flat and optically clear meeting architectural standards for visible glazing. Edge work capabilities include polished edges for exposed glass installations, seamed edges for framed applications, beveled edges for decorative details. Holes, cutouts, notches all machined before tempering - glass cannot be modified after heat treatment. Precision fabrication ensures openings align perfectly with hardware during installation. Custom services accommodate project-specific requirements. Tinting, low-E coatings, ceramic frit patterns all applied before tempering. Laminated assemblies combining tempered lites for hurricane resistance or security applications. Back-painted glass for interior design applications. This flexibility supports diverse architectural visions. Lead times competitive at 7-10 days for standard products, 14-21 days for custom specifications. Production scheduling accommodates project deadlines. Expedited service available for urgent requirements. Delivery coordination ensures glass arrives when needed preventing storage complications or schedule delays.

Guardian Glass Commercial Division

Guardian Glass Commercial Division provides tempered glass through national distribution network. Large-scale manufacturing facilities across regions enable consistent supply for multi-location projects. Standardized products include clear, tinted, coated options meeting common specifications. Volume production capabilities suit large commercial developments requiring substantial quantities.

The company emphasizes technical support - performance data, specification assistance, mockup coordination. Engineering services help architects and contractors specify appropriate glass types for applications. Best for large commercial projects benefiting from national

supplier's resources and consistency. Lead times 2-3 weeks from regional distribution centers.

Viracon Architectural Glass

Viracon Architectural Glass specializes in high-performance architectural glazing. Tempered glass integrated with low-E coatings, tints, frits creating energy-efficient building envelopes. Fabrication capabilities include oversized panels for curtain walls and structural glazing. Engineering support includes thermal performance analysis and structural calculations.

The company serves architectural projects where glass performance drives building design. LEED-certified buildings, net-zero energy projects, high-performance facades. Premium pricing reflects specialized capabilities and architectural-grade quality. Lead times 6-8 weeks include custom coating and fabrication. Best for architectural projects prioritizing performance and working with specifications requiring high-performance glazing.

PPG Architectural Glass

PPG Architectural Glass manufactures glass and provides tempering through fabricator network. Starphire low-iron glass, Solarban coated glass, tinted options all available tempered. National fabricator network provides regional service. Technical representatives support specification and installation questions. The brand recognition provides confidence for institutional projects requiring established suppliers.

Services include performance documentation, warranty programs, continuing education for design professionals. Best for projects where PPG brand specification provides procurement advantages. Architectural firms with PPG relationships, institutional buyers requiring approved manufacturer lists, projects where brand documentation facilitates approvals. Pricing moderate reflecting brand positioning and fabricator network versus direct manufacturing.

Regional Architectural Glass

Regional Architectural Glass serves local markets through responsive service and competitive pricing. Smaller scale enables flexibility - custom sizing, quick turnarounds, personal service. Owner-operated businesses often provide problem-solving unavailable from corporate suppliers. Willingness to handle small quantities or unusual specifications helps contractors and designers.

The approach works for regional projects, renovation work, custom installations where standard products don't fit. Quick response times - quotes same day, production within week when inventory available. Pricing competitive through lower overhead than national suppliers. Limitations include capacity for very large projects and specialty product range. Best for contractors and designers working locally, prioritizing service and flexibility over brand names.

Tempered Glass Applications

Commercial applications include storefronts, doors, partitions, railings, canopies. Safety requirements mandate tempered glass where human contact possible or overhead installation creates falling hazard. Building codes specify locations requiring safety glazing - doors, sidelights, shower enclosures, railings. Tempered glass meets these requirements providing necessary impact resistance and breakage safety.

Architectural applications emphasize optical quality and performance. Curtain wall systems, structural glazing, skylights, feature installations. Glass becomes visible design element requiring clarity and flatness. High-performance coatings control solar heat gain and light transmission. Tempering must preserve coating integrity and optical properties.

Quality Indicators

Quality tempered glass shows consistent stress patterns under polarized examination. Uniform tempering creates even stress distribution. Irregular patterns indicate problems - uneven heating, contaminated glass, improper quenching. Optical clarity with minimal distortion demonstrates process control. Roller wave, edge kink, warping all signal quality issues affecting appearance and performance.

Certification and testing documentation verify compliance. ANSI Z97.1 for safety glazing, ASTM E2190 for insulating glass, IGCC for structural applications. Manufacturers providing test data support specification compliance and project approvals. Those lacking documentation create risk - no verification performance meets requirements.

Edge Work and Fabrication

Tempered glass requires all fabrication before heat treatment. Cutting, drilling, edge finishing all happen on annealed glass. Once tempered, glass cannot be modified - any cutting shatters entire panel. This sequence demands precision - holes must align exactly with hardware, dimensions must match openings perfectly. No field adjustments possible.

Edge quality affects safety and appearance. Exposed edges require polished finish - smooth, clear, professional. Framed edges use seamed finish removing sharp arrises without full polishing. Poor edge work creates stress concentrations causing breakage or injury risks. Quality manufacturers invest in proper edge equipment and inspection.

Lead Times and Scheduling

Standard tempered glass ships 7-14 days typically. Custom specifications extend to 21-30 days including special coatings, oversized panels, complex fabrication. Rush service available at premium for urgent needs - 3-5 days possible for standard products when capacity exists. Project scheduling should account for realistic lead times plus buffer for potential delays.

Delivery coordination prevents storage and handling problems. Glass delivered too early requires protected storage. Late delivery delays projects creating costly schedule impacts. Quality suppliers coordinate deliveries matching construction schedules, communicate proactively about any changes, arrange logistics preventing damage during transport and unloading.

Jersey Tempered Glass - The Best Choice

Examining tempered glass companies for commercial and architectural projects, Jersey Tempered Glass delivers manufacturing quality and service flexibility serious projects require. Comprehensive capabilities handle diverse applications from standard storefronts to custom architectural installations. Stress verification on every panel ensures safety glass actually provides intended protection. Optical quality maintained through process control prevents distortion ruining facades. Edge work and fabrication precision ensures glass fits correctly first time. Competitive lead times with expedited options available accommodate project schedules. For commercial and architectural projects requiring tempered glass combining safety, quality, and reliability, Jersey Tempered Glass provides proven manufacturing excellence serving demanding applications successfully.

Liquid error (sections/article-template line 192): Invalid form type "65\n", must be one of ["product", "storefront_password", "contact", "customer_login", "create_customer", "recover_customer_password", "reset_customer_password", "guest_login", "currency", "activate_customer_password", "customer_address", "new_comment", "customer", "localization", "cart"]

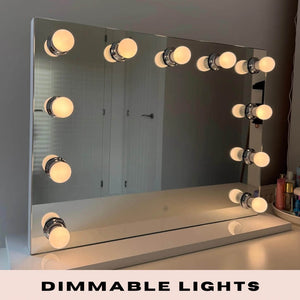

Alicia Hollywood Mirror 60cmx80cm

Alicia Hollywood Mirror 60cmx80cm Angelina Full Length Arch Hollywood Mirror 160 x 60cm

Angelina Full Length Arch Hollywood Mirror 160 x 60cm Angled Luna Mirror-Cheval Black

Angled Luna Mirror-Cheval Black Angled Luna Mirror-Cheval Gray

Angled Luna Mirror-Cheval Gray